The AI factory will include 10,000 GPUs, featuring Nvidia DGX B200 systems and RTX PRO Servers.

June 12, 2025

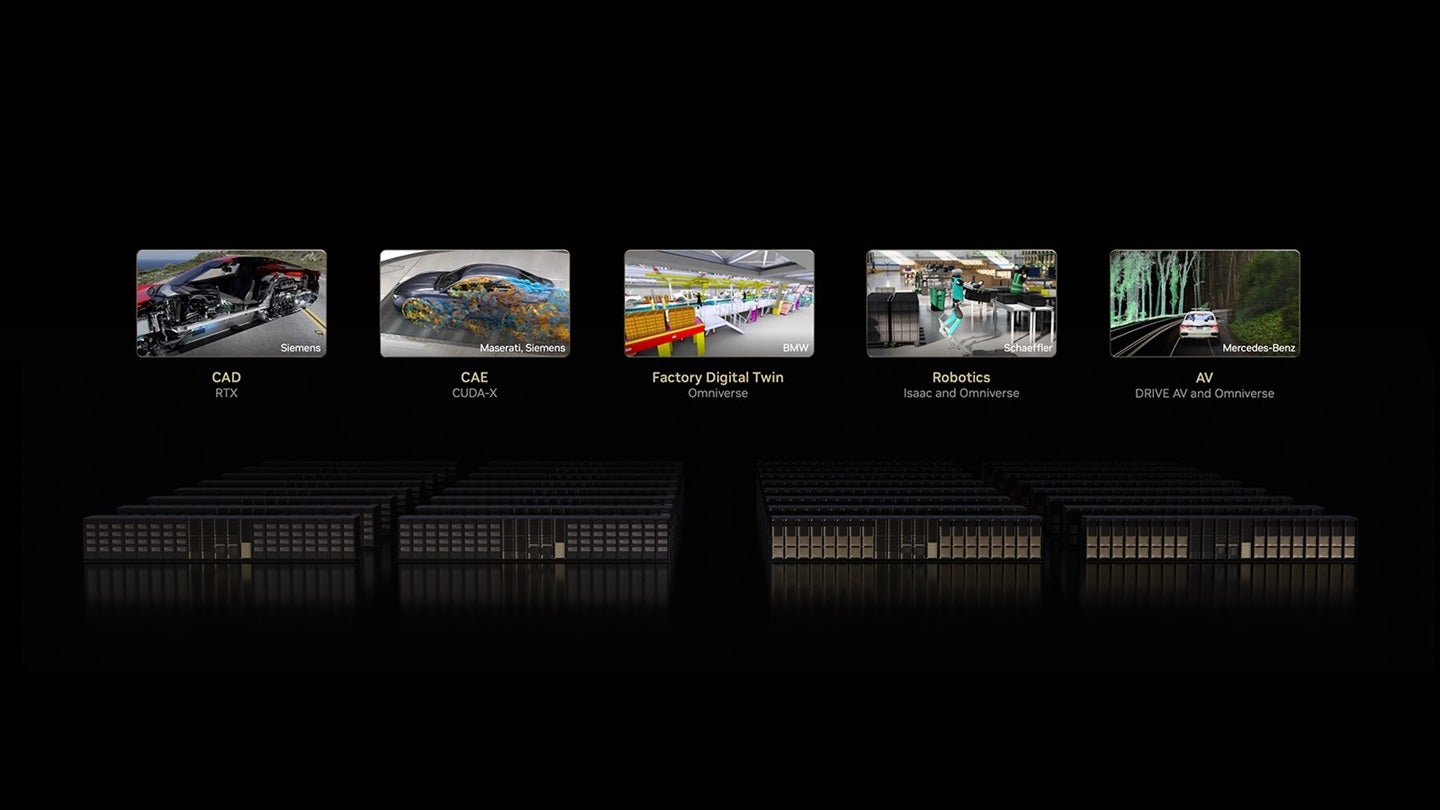

The AI factory will leverage Nvidia CUDA-X libraries, RTX, and Omniverse to accelerate workloads. Credit: NVIDIA Corporation.

The AI factory will leverage Nvidia CUDA-X libraries, RTX, and Omniverse to accelerate workloads. Credit: NVIDIA Corporation.

Nvidia has announced that it is developing the “world’s first” industrial AI cloud in Germany to support European manufacturers.

This AI factory will feature 10,000 GPUs, including Nvidia DGX B200 systems and RTX PRO Servers, enabling enhancements in design, engineering, simulation, digital twins, and robotics.

European manufacturers like BMW Group, Maserati, Mercedes-Benz, and Schaeffler are leveraging Nvidia-accelerated applications from software providers such as Ansys, Cadence, and Siemens to transform their product lifecycles.

These applications facilitate simulated product design, factory planning, AI-driven operations, and logistics.

The AI factory will utilise Nvidia CUDA-X libraries, RTX, and Omniverse-accelerated workloads, following the Nvidia Omniverse Blueprint for AI factory design.

Cadence’s Reality Digital Twin Platform will simulate and optimise the facility in a virtual environment.

GlobalData Strategic Intelligence

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData

Nvidia founder and CEO Jensen Huang said: “In the era of AI, every manufacturer needs two factories: one for making things, and one for creating the intelligence that powers them.

“By building Europe’s first industrial AI infrastructure, we’re enabling the region’s leading industrial companies to advance simulation-first, AI-driven manufacturing.”

Major software vendors are integrating Nvidia’s AI-physics technologies and Omniverse platform to enhance their offerings.

Maserati is using Siemens’ Omniverse-powered solutions to visualise airflow over car bodies, while Ansys incorporates Omniverse into its Fluent software for fluid simulations.

Volvo Cars has achieved a 2.5x acceleration in fluid simulations for its EX90 electric vehicle using Ansys Fluent on Nvidia Blackwell GPUs, the company claims.

Cadence’s Millennium M2000 Supercomputer, combined with Nvidia technologies, accelerates AI-driven simulations for various industries.

Ascendance has achieved a 20x reduction in simulation runtimes for aviation designs using Cadence Fidelity software and Nvidia GPUs.

Schaeffler is adopting Nvidia’s physical AI stack for digital factory planning and robotic training across its more than 100 plants, utilising Siemens’ Omniverse applications alongside partners like Microsoft Azure Industrial Cloud.

BMW Group is creating plant-scale digital twins with Nvidia Omniverse libraries for real-time collaboration and autonomous robot development, while Mercedes-Benz is using Omniverse to optimise factory assembly lines.

In May 2025, the company extended its partnership with Foxconn Hon Hai Technology Group to develop an AI factory in Taiwan.

English (US) ·

English (US) ·